Plastic CNC Machining for Rapid Turnaround and Maximum Repeatability

CNC machining, or Computer Numerical Control machining, refers to several operations that remove material from a solid workpiece, such as routing, drilling, cutting, or polishing. Pre-programmed software controls and guides the movement of cutting tools to achieve part features and profiles based on a CAD drawing. The result is exceptional consistency from part to part with very low error rates.

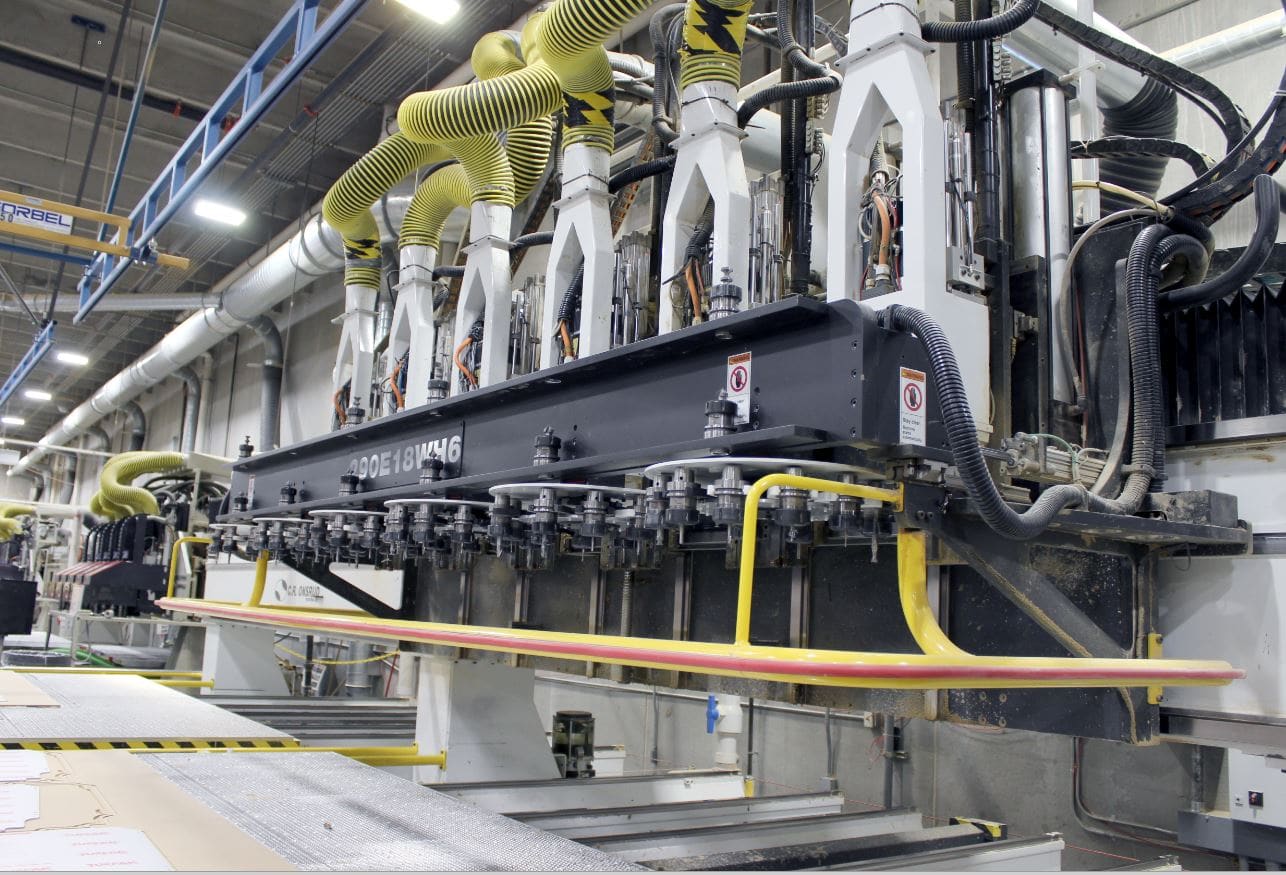

While commonly used with metal, CNC machining equipment is also compatible with many other materials, including plastics. Aubright specializes in plastic CNC machining of parts and components that meet the needs of OEMs, powersports manufacturers, retail brands, and others. Our advanced equipment makes precision parts at scale, keeping our customers efficient, competitive, and innovative. Learn more about plastic CNC machining and our capabilities.

Benefits of Aubright’s Plastic CNC Machining Services

CNC machining has several significant advantages for production, especially when working with an experienced team like Aubright. For example:

- Minimal Waste. Programming exact movements into the equipment means each piece is drilled, cut, or shaped identically. As a result, there are fewer errors that lead to wasteful scrap or rework. This is especially important for high-value plastics like acrylic or polycarbonate.

- Accuracy and Precision. CNC instructions are based on computer drawings of parts with the exact dimension and tolerance requirements. The instructions are repeated on each cycle, and the workpiece is held in alignment with fixturing. Because of this, each finished workpiece is a match for the part print and falls within tolerances.

- Fast and Efficient. Because it is largely automated, CNC machining is quick, with little downtime compared to manual processes performed by staff. We also use multi-head and 5-axis routing and other equipment to create complex parts quickly for faster turnaround.

- Simplified Assembly. Because it is so accurate and precise, CNC machining produces parts that fit into assemblies easily and that require few manual adjustments.

- Lower Production Costs. Taken together, the speed, accuracy, and low waste of CNC machining reduces costs for materials and labor.

5-Axis Routing: Taking CNC Machining to the Next Level

The capabilities and benefits of CNC technology take routing quite literally to a whole new dimension. With multiple-axis robotic heads, this process trims and routes out material to make parts with deep features or that have multiple surfaces and angles – all from one setup.

Aubright’s 5-axis routing capabilities offer even greater flexibility and performance. In 5-axis routing, the cutting tool can move along three linear axes (X, Y, and Z) and two rotational axes in any combination, which gives access to multiple sides of a part without having to reposition it.

Benefits of 5-Axis routing include:

- Simplifies creation of complex, multi-surface designs

- Less set-up and changeover time

- Reduction of manual repositioning

- Improved precision and repeatability

- Less wasted material for cost savings

Plastics Compatible with CNC Machining

At Aubright, we work with a wide range of plastics so you get the right balance of performance, durability, and cost. Material options include:

- ABS. ABS plastic offers high impact strength and toughness. It can be painted, welded, and finished in multiple ways for use in a range of structural components.

- Acrylic (PMMA). Acrylic is tough and very clear. It is well-suited for signs, displays, and enclosures. It also resists scratches and is easily bonded with specialized cements.

- High-Density Polyethylene (HDPE). Polyethylene is easy to machine, yet it has good strength and durability while being chemically resistant.

- PETG. This material is cost-effective, clear, and has excellent formability for indoor signs and protective coverings.

- Polycarbonate (PC). Polycarbonate is among the strongest and most durable plastics, making it a top choice for applications that require impact resistance.

- Polystyrene (Styrene). This material has excellent machinability due to the fact that it is easily cut, shaped, and drilled. It is also extremely cost-effective.

- PVC. PVC is a durable, lightweight plastic with excellent chemical and flame resistance. It is often used for industrial and construction applications.

Common Applications for Plastic CNC Machining

CNC machining is a smart choice for high-precision applications in any industry, including manufacturing components for OEM companies. Our services support these and other markets and products:

- Powersports equipment

- Retail displays and fixtures

- Automation and robotics

- Automated packaging and material handling

- Food processing

- Medical devices, housings, and enclosures

- Semiconductor cleanrooms

High-Quality Plastic CNC Machining with Aubright

At Aubright, CNC machining services have one goal: to help customers succeed. We offer precision cutting, trimming, and routing technologies for maximum repeatability, fast turnaround, and consistent quality, every time. Contact us to learn more about plastic CNC machining and how we can help bring your next project to life.